DB Schenker’s 3D printing and virtual warehousie for spare parts logistics

28 / 09 / 2022

Source: DB Schenker

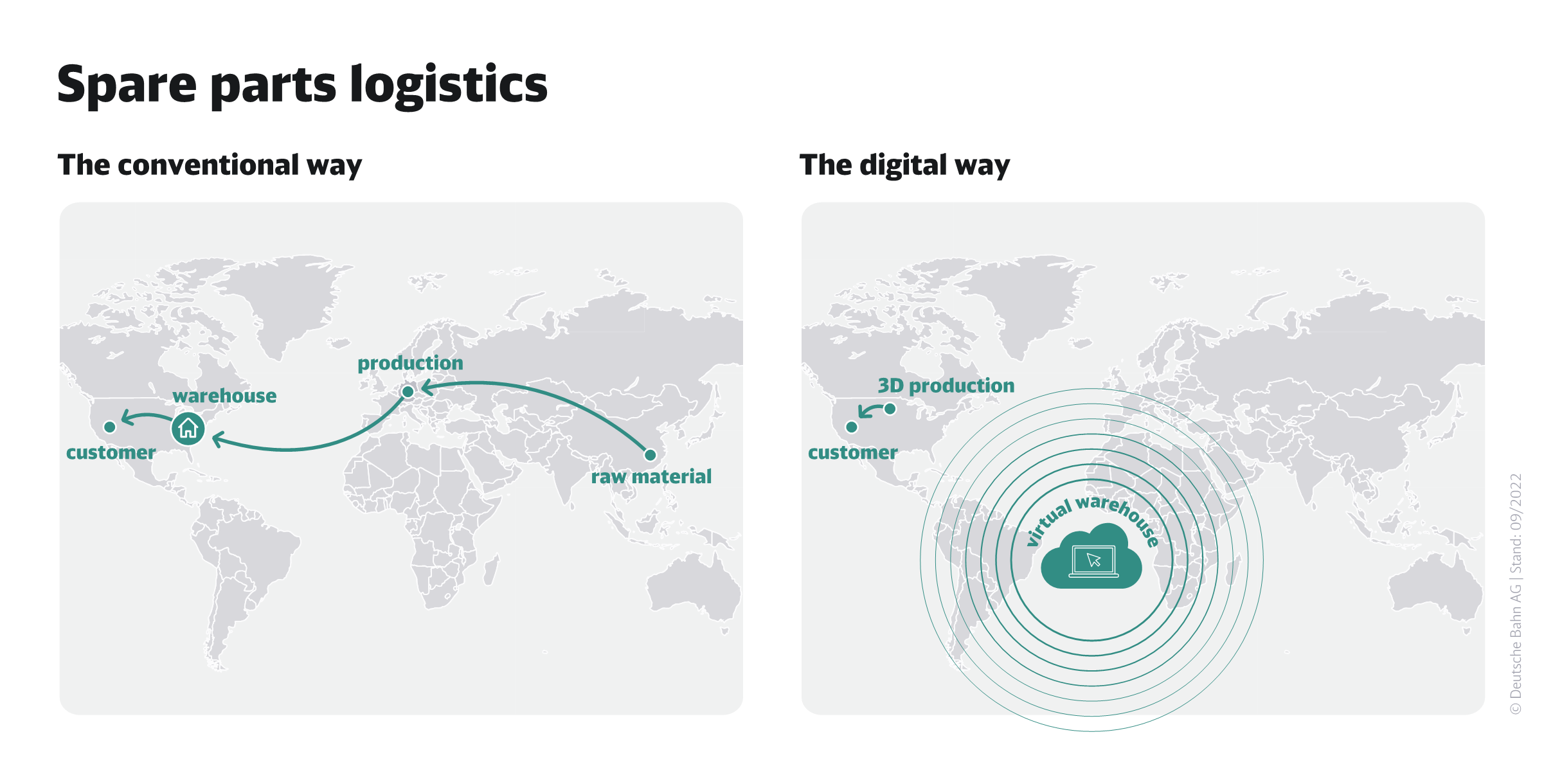

Logistics provider DB Schenker is offering 3D printing and virtual warehousing in what it says will make spare parts supply chains becomes faster, cheaper, and more sustainable.

DB Schenker CEO Jochen Thewes said: “We are the first global logistics provider to offer spare parts delivery via 3D printing. Products from our virtual warehouse are available in a very short time and are manufactured exactly where they are needed.”

Speaking at DB Schenker’s first Product Show conference in Frankfurt, Thewes said that the virtual warehouse lowers delivery costs, shortens delivery times, and protects the environment.

He added: “This exemplifies what the logistics of the future can do for customers. The aim is to avoid unnecessary warehousing and to make supply chains even more stable and flexible.”

Thewes observed that, in the face of increasing challenges in global logistics, digital innovations such as spare parts deliveries via 3D printing create real added value for customers in many areas.

“We want to shorten distances and at the same time keep products available faster and cheaper. To achieve this, we are fully committed to digital innovations.”

In pilot projects, DB Schenker has already successfully tested the virtual warehouse, designed for customers from the mechanical engineering, automotive, and rail transport markets.

Parts were produced on demand close to the customer. Without pre-production and storage, on-demand production reduces capital commitment costs.

The new Schenker service with a virtual warehouse is now being offered to a wide range of customers worldwide.

DB Schenker collaborates closely with German parent Deutsche Bahn, which already has experience in 3D printing – with 80,000 parts manufactured from various materials and technologies. “According to our findings, up to 10% of companies’ inventories can be manufactured on site,” said Thewes.

Spare parts that are needed relatively infrequently and parts that have to be stored in large numbers due to high minimum purchase quantities are particularly suitable for 3D printing. The virtual storage of the components is done by the upload of the 3D blueprints in the cloud.