The right stuff: How software can optimise ULD loadplanning

08 / 04 / 2019

Optimised loading of an air cargo container or pallet is like solving a Rubrik’s Cube, but without the fun.

Cargo-Planner is now applying its software expertise in ocean and rail freight container to the world of airfreight unit load devices (ULD), with their awkward shapes and regulatory status as an aircraft component.

Erik Törnblom, the founder of Cargo-Planner, has secured his first airfreight-only customer, described as a big client at Heathrow, which is now using the company’s 3D planning system for loading ULDs.

Given that Cargo-Planner has been in business for more than five years serving the deepsea container and railfreight markets, why the move into the delicate world of air cargo ULDs by releasing this new module?

“We have a large number of clients in seafreight and it has been a busy time reaching out to potential customers, because pallets are different in shape and not as easy to deal with as in ocean container or equipment you place on a truck.”

Adds Törnblom: “We still see ourselves as a start up. It takes time for a new player to get access to people, to get the tools inside the company and to test them, and it takes time to change behaviour.”

A steel 20ft (teu) or 40ft (feu) maritime container is a different and heavier beast to the less robust ULD or airfreight pallet that will often reside in a passenger aircraft rather than a 22,000 teu boxship.

“The software has the most commonly used ULD and pallets available in the program library, but if there is a piece of equipment with non-standard dimensions, then you can also create easily your own ULD by entering the size of the containers and also the contours.”

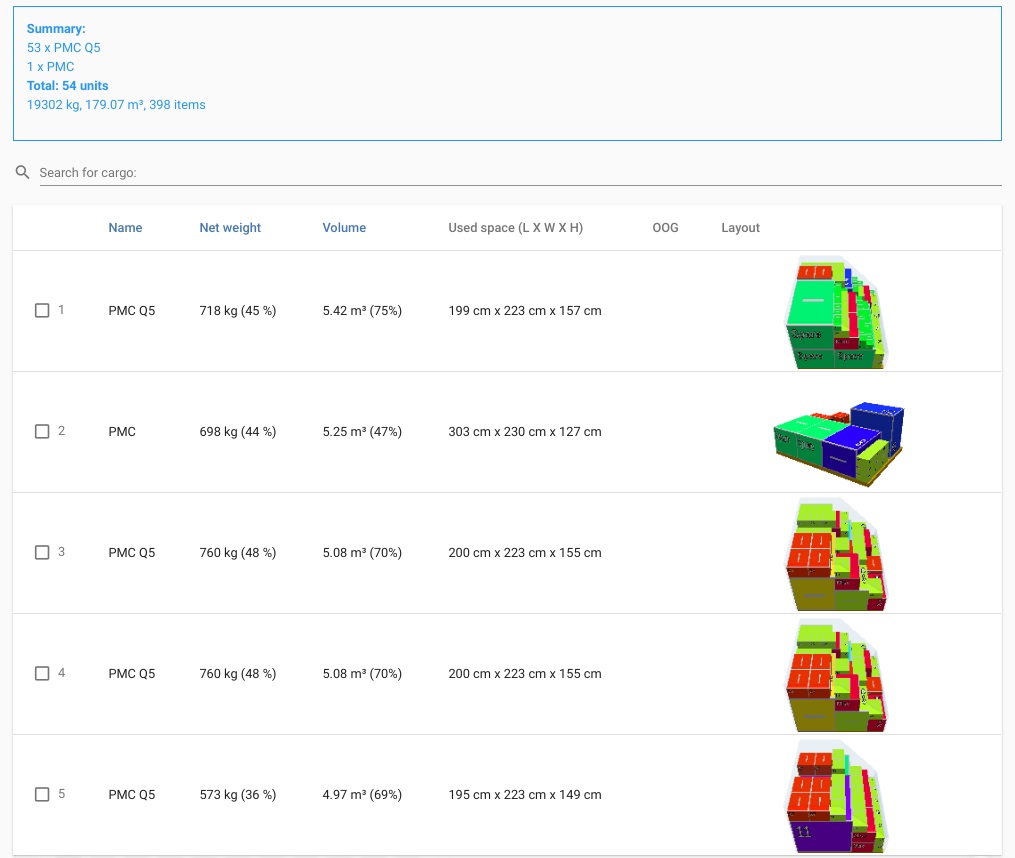

Once installed, the user starts with a packing list, the number of items, their individual weight and size, and then he or she selects the type of equipment (container) available for this particular load line.

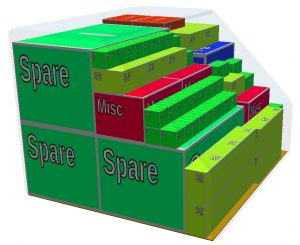

At a push or a button or click of a mouse, the software begins calculating the optimal loading profile.

A person performing the same task would take in several factors, such as balancing the most efficient use of space with the ease of loading and unloading the ULD, in order to save time.

Said Törnblom: “Most of our clients use this program to get an idea of roughly what number and types of containers they can use. If you have 1,000 packages, no-one can follow blindly the loadplan on paper, so the tool allows them to see if the shipment will fit. If it does, then the company can estimate how many and what type of containers are needed.”

He continued: “You can set rules for the packing list as well, for example, some cargo is not stackable and there may be a certain number of layers that you can stack packages.

“You can do the calculation if you have a specific requirement as to how things are to be packed.”

In practical terms, the final load plan is sent to the terminal, where the packers can see where the largest piece should sit in the container and how the rest should be stacked: “The loadplan is used more as a guide,” added Törnblom.

If the operator wants to adjust the computerised solution, then it is possible to move individual pieces around in the virtual ULD seen on the screen. That final human intervention is useful.

Said Törnblom: “Sometimes a human being has a better solution than a computer program will ever do. This is because the operator or packer has some specialist knowledge that the computer does not have.

“A computer can very quickly give you a good estimate, but in the end you need a human being because it is often a balance between guidance and blindly following the manual.”

This is not a criticism of the software because if the program was unfettered and could spend an eternity working on the optimal loadplan, it would trying out the millions of possible package positions within a ULD or pallet. The end result could take hours, if not days.

Something called an approximation algorithm means that the software comes up with a load plan which is most optimal for 90% of the time.

Another benefit, said Törnblom, is that suggested loadplans can be used when bidding for a contract, providing the potential customer with a good idea of how their goods will be packed.

That also means the customer knows that the optimal, and most economic, solution has been planned.

Said Törnblom: “A company has to give a potential customer the most accurate price as possible. If you don’t use this software, it may mean you are using more containers than are actually needed, with a higher than the competitors, and you lose the deal.

“Using cargo planning software gives you more safety when bidding for a contract.”